Do portable generators need to be grounded?

For safety reasons, it is really necessary to ground a portable generator. When a generator is not properly grounded, the risk of electric shock and fire increases. Grounding helps prevent the build-up of static electricity and reduces the risk of electrical overload. It also provides a path for excess current to safely dissipate to ground. Without proper grounding, the risk of electrical hazards is higher, especially in wet conditions. Therefore, be sure to follow the manufacturer’s instructions for grounding your portable generator to ensure safe operation.

Mobile generator sets are suitable for construction sites, large-scale breeding sites, field mining, outdoor media interviews, etc. Therefore, they need to be grounded and pay attention to safety.

Following the correct operation method of the mobile generator set can extend the service life of the generator set. YDQ Power recommends that customers refer to the mobile generator set operating instructions manual to understand the reasons for grounding during use.

The reasons for grounding during use

Working ground

Working grounding is to ground the neutral point for the following purposes:

Reduce electric shock voltage. In a system where the neutral point of the generator set is not grounded, when one phase is grounded and the human body touches the other two phases, the electric shock voltage is more than 1.7 times the phase voltage; while for a system with a grounded neutral point, the electric shock voltage drops to close to or equal to phase voltage.

Quickly shut down faulty equipment. In a system where the neutral point is not grounded, when the phases are grounded, the capacitance and insulating resistance between the conductors and the ground can form a current path. The grounding current is very small, which is not enough to cause the protective device to operate and cut off the power supply, which cannot ensure personal safety; and for In a neutral point grounding system, when a phase is grounded and the ground current is large, the protection device will act quickly to disconnect the fault point.

Reduce the grounding level of electrical equipment. In a system with an ungrounded neutral point, when one phase is grounded, the voltage to ground of the other two phases will rise to the line voltage; for a system with a grounded neutral point, when one phase is grounded, the voltage to ground of the other two phases will rise. It is only close to the phase voltage, so it can reduce the insulation level of electrical equipment and transmission lines.

Protective grounding

Generator set protective grounding is often used in low-voltage systems where the neutral point is not grounded. Its function is: when the insulation structure of a certain winding of the motor has been damaged and the shell is charged, if it is not grounded and the human body touches the shell, it is equivalent to a single-phase electric shock, which may Risk of electric shock occurs. If protective grounding is used, when the human body touches the shell, since the resistance of the human body is connected in parallel with the ground resistance, the resistance of the human body is much greater than the ground resistance, so the current passing through the human body is very small, and there is no risk of electric shock.

Protection connected to zero

Protective zero connection is often used in low-voltage systems where the neutral point is grounded. Its function is: when the insulation structure of a certain winding of the motor has been damaged and is connected to the shell, the protective zero connection is used to form a single-phase short circuit. The current can quickly cause the phase to be short-circuited. The fuse in the circuit breaker blows, and the casing is no longer charged. Even if the human body touches the casing before the fuse blows, the resistance of the human body is much greater than the resistance of the circuit, and the current passing through the human body is very small, so there is no risk of electric shock.

The installation of mobile generator sets skills.

Below, YDQ Power will teach you the installation skills of mobile generator sets step by step.

Mobile units are mainly installed on movable platforms such as cars, trailers or trailers, and their installation layout requirements are as follows.

1. The platform should be chosen in a solid, flat and dry place. Under normal circumstances, the platform and the ground do not need to be fixed, but the chassis of the unit should be ensured to be stable.

2. Check the connection firmness and correctness of each connection part, especially the connection of foot bolts, couplings, generator and excitation system, etc.

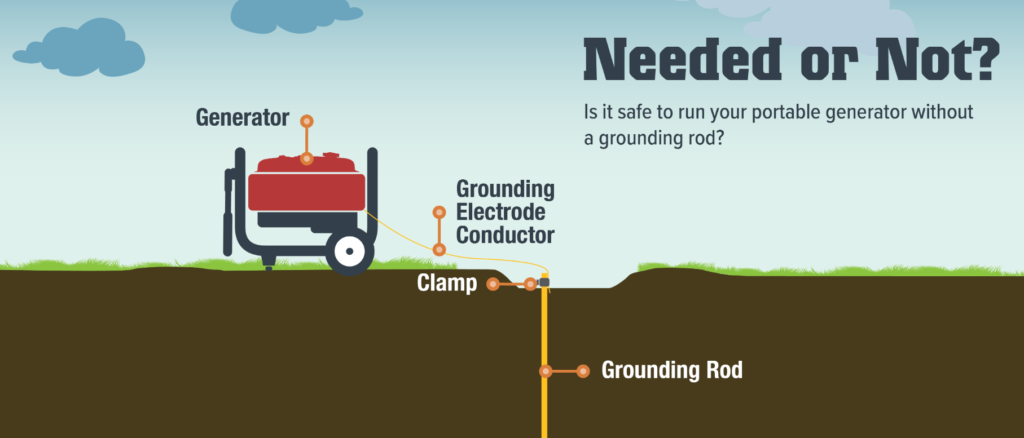

3. Bury the equipment’s grounding device in accordance with regulations and securely connect the grounding wire. When the diesel generator set is working in the open air, necessary measures should be taken to prevent rain, moisture, snow, sun and wind and sand to avoid electric shock accidents and maintain the normal working performance of the unit.