What is inverter generator?

An inverter generator is a portable generator that uses an electronic alternator to generate electricity. Inverter generators use advanced technology to convert direct current (DC) electricity generated by the engine into alternating current (AC) electricity, which can be used in various household appliances or tools. It is designed to produce clean, stable electricity to make the most efficient use of fuel and minimize emissions.

The output frequency of traditional generators is usually fixed and cannot be adjusted. By introducing inverter technology, variable frequency generators can change the frequency and voltage of the input power supply, thereby achieving precise control of the generator output frequency.

How does an inverter generator work?

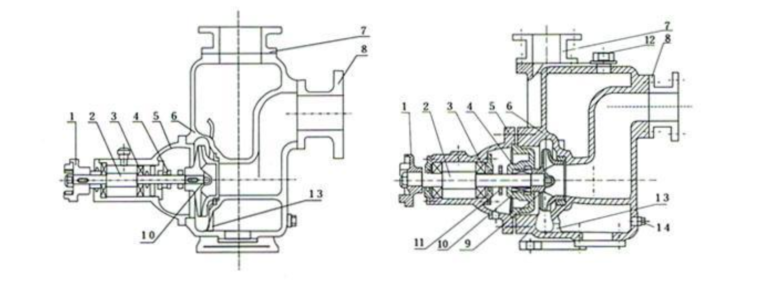

Generators are usually composed of stators, rotors, end covers, brushes, bases, bearings and other components. The stator consists of a machine base, stator core, wire wrap windings, and other structural parts that fix these parts. The rotor consists of the rotor core, rotor magnetic poles (with magnetic yoke and magnetic pole windings), slip rings (also known as copper rings and collector rings), fans and rotating shafts.

The stator and rotor of the generator are connected and assembled through the bearing, base and end cover, so that the rotor can rotate in the stator. A certain excitation current is passed through the slip ring to make the stator become a rotating magnetic field, and the stator coil moves to cut the magnetic lines of force. , thus generating an induced electric potential, which is drawn out through the terminal block and connected in the circuit to generate a current. Because there is a break in the connection between the brush and the rotor, the rotor rotates in a certain direction, generating an alternating current. Therefore, the alternating current in household circuits and other circuits is referred to as alternating current.

What are the benefits of an inverter generator?

Energy efficient

The variable frequency generator adopts frequency converter technology, which can adjust the output frequency and voltage according to actual needs to avoid wastage of energy. Compared with traditional generators, inverter generators can operate at lower frequencies and voltages when the load is lighter or low power is required, thereby improving energy efficiency and saving effects.

Precise control

By adjusting the input power through the frequency converter, the variable frequency generator can achieve precise control of the output frequency and voltage. This can meet different load requirements and adapt to different work scenarios. For example, in some precision equipment, stable voltage and frequency supply are required, and variable frequency generators can meet this precise control demand.

Quick response

Thanks to the inverter technology, the response speed of the inverter generator is very fast. It can adjust the output frequency and voltage in a short time to adapt to rapid changes in load. This makes variable frequency generators advantageous in certain applications that require fast response, such as elevators, flight simulators, etc.

High reliability

Variable frequency generators generally have high reliability and stability. The use of advanced inverter technology and electronic components helps reduce failure rates and increase equipment life. In addition, the variable frequency generator also has self-diagnosis and protection functions, which can detect and handle abnormal situations in a timely manner and protect the safe operation of the equipment.

Pros and cons of inverter generator

Advantage of inverter generator

Low fuel consumption

An inverter generator does not need to run at 3600 rpm all the time to produce AC power. Engine speed automatically adjusts based on the power consumed by the connected load. If the load is smaller, the engine will run at a lower speed, thereby reducing fuel consumption. A conventional generator, on the other hand, operates continuously at 3600 RPM, regardless of the power consumed by the connected load.

Clean power supply

The alternating current generated by an inverter generator has no harmonic distortion and is safe for use with small electronic equipment. The output form of AC power is a pure sine wave, which is known to not damage sensitive electronic equipment such as household appliances and medical equipment.

Parallel operation

If one inverter generator is not enough to meet your power needs, you can combine multiple inverter generators to get the required power output. This is something traditional generators cannot do.

Portability

Most of the inverter generators on sale are small and easy to carry around. Their portability makes them an ideal backup power solution when camping. For example, YDQ Power SE3300iE-C portable power station. It weighs an impressive 23kg and has a capacity of 2800Wh and a power of 3000W – making this power source perfect for powering all your devices and appliances during any trip.

Low noise

Because the generator operates at a variable speed, it is less noisy than a traditional generator. The noise level is acceptable and will not disturb you during your camping holiday.

Disadvantage of inverter generator

High cost

Inverter generators cost more compared to traditional generators. This is because they are equipped with efficient inverter technology for complex designs and circuits. But trust us, an inverter generator is worth every penny you spend on it.

Low power output

The power output of an inverter generator is much less than that of a typical alternator. But it’s more than enough for common household electronics and small appliances.

Scenes to be used

Inverter generators use gasoline to run their engines. Therefore, it emits gases such as carbon monoxide. It is not safe to use indoors.

High maintenance costs

The working principle of a variable frequency generator is slightly more complex than that of an ordinary generator, the accessories it contains are more expensive than an ordinary generator, and the maintenance cost is higher than that of an ordinary generator.

Conclusion

When we choose a variable frequency generator, we must consider comprehensive factors, including power, cost, noise, usage scenarios and other factors.